Professional’s Ranking

Professionals

- Constructed-in digicam

- Nicely priced

- Spectacular print high quality

Cons

- Single color printing solely

- Might be very noisy

- Irritating to alter filament

Our Verdict

The Creality K1C is a formidable 3D printer that provides a shallow studying curve for newcomers. It’s dependable, quick and might print all kinds of filaments out of the field

If you happen to just lately purchased a Creality K1, then I’d advise you to cease studying this overview now as it’ll solely make you unhappy.

The K1 is barely about six months previous, however is already being changed by the K1C. It’s no secret that the K1 had some teething issues and Creality ended up redesigning the new finish, fixing some software program points and open sourcing the software program that ought to have been open supply all alongside.

However as a substitute of simply persevering with to promote the ‘mounted’ K1, Creality determined to do an entire overhaul and launch a very new mannequin, the K1C.

It would look the identical, however beneath the pores and skin there are a raft of upgrades and enhancements that make it a greater printer. So, apologies to anybody who’s simply purchased a K1.

Options & design

- New extruder

- New easy-swap hardened nozzle

- AI digicam as normal

Let’s begin with the C. When rumours of the printer began showing, some thought it stood for Color. Would Creality observe Bambu Lab and launch a printer just like the P1S Combo that may print with as much as 4 colors?

Sadly not. The C truly stands for Carbon, and means there’s an upgraded, hardened metal nozzle that’s designed to take care of a temperature of 300°C.

The C truly stands for Carbon, and means there’s an upgraded, hardened metal nozzle that’s designed to take care of a temperature of 300°C

This is likely one of the K1C’s massive differentiators: it might reliably print abrasive carbon-fibre-infused filaments comparable to PLA-CF and PETG-CF in addition to people who require greater temperatures comparable to ASA and PC.

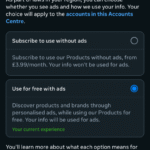

Alongside the ‘unicorn’ nozzle, as Creality is asking it, the all-metal direct-drive extruder is stronger than the unique K1’s, permitting it to extra reliably feed filament into the hotend.

Jim Martin / Foundry

The corporate says the nozzle is meant to be fast to swap out, however except I’m doing it flawed, it’s nonetheless way more laborious than the Bambu A1, for instance. The new finish is mounted on the rear of the print head, and the quilt (containing the fan) isn’t held in place by magnets: you need to undo two screws. You have to take away this so as to take away the silicone shroud that sits over the nozzle. Then you could unscrew the nozzle utilizing the provided spanner – hardly the one-handed swap Creality advertises.

The actual fact is, you’re not more likely to need or want to alter the nozzle fairly often anyway, making this all fairly moot for most individuals.

The all-metal direct-drive extruder is stronger than the unique K1’s, permitting it to extra reliably feed filament into the hotend

The K1 doesn’t have a digicam, however it’s normal on the K1C. It means that you can test on print progress remotely and report timelapses of prints for posterity. It’s referred to as an AI digicam as a result of it might detect international objects on the construct plate or if a print fails half means via and the filament begins to type a load of ‘spaghetti’.

So far as I can inform it’s the identical digicam from the K1 Max so high quality is fairly first rate. It isn’t good on the AI stuff, although, and doesn’t all the time discover and warn you of failed prints. It’s fairly good at recognizing while you’ve left the earlier mannequin on the construct plate, forgotten about it and began one other print although.

Past this, you’d be hard-pushed to identify the adjustments and enhancements. However they’re there. Creality says the body “adopts larger elements made by built-in die casting. With fewer seams, it appears to be like neat and turns into totally sturdy”.

Jim Martin / Foundry

It actually feels sturdy, and there’s now a metallic plate on the entrance fringe of the mattress, presumably so as to add additional power. Nevertheless, the cynic in me sees it as a replica of what Bambu has finished with its construct plates, even all the way down to slapping the construct quantity on it: 220x220x250mm. (Pedants will spot – and be irked by – the inaccurate ³ on the finish.)

Elsewhere, there’s a carbon filter (because the K1 Max has) which helps to maintain nasty particles from being blown into your room, massive rubber ft which come already hooked up (to dampen vibrations) and a Bambu-style silicone strip caught to the rear of the construct plate for wiping the nozzle clear.

By way of meeting, there’s just about none to do

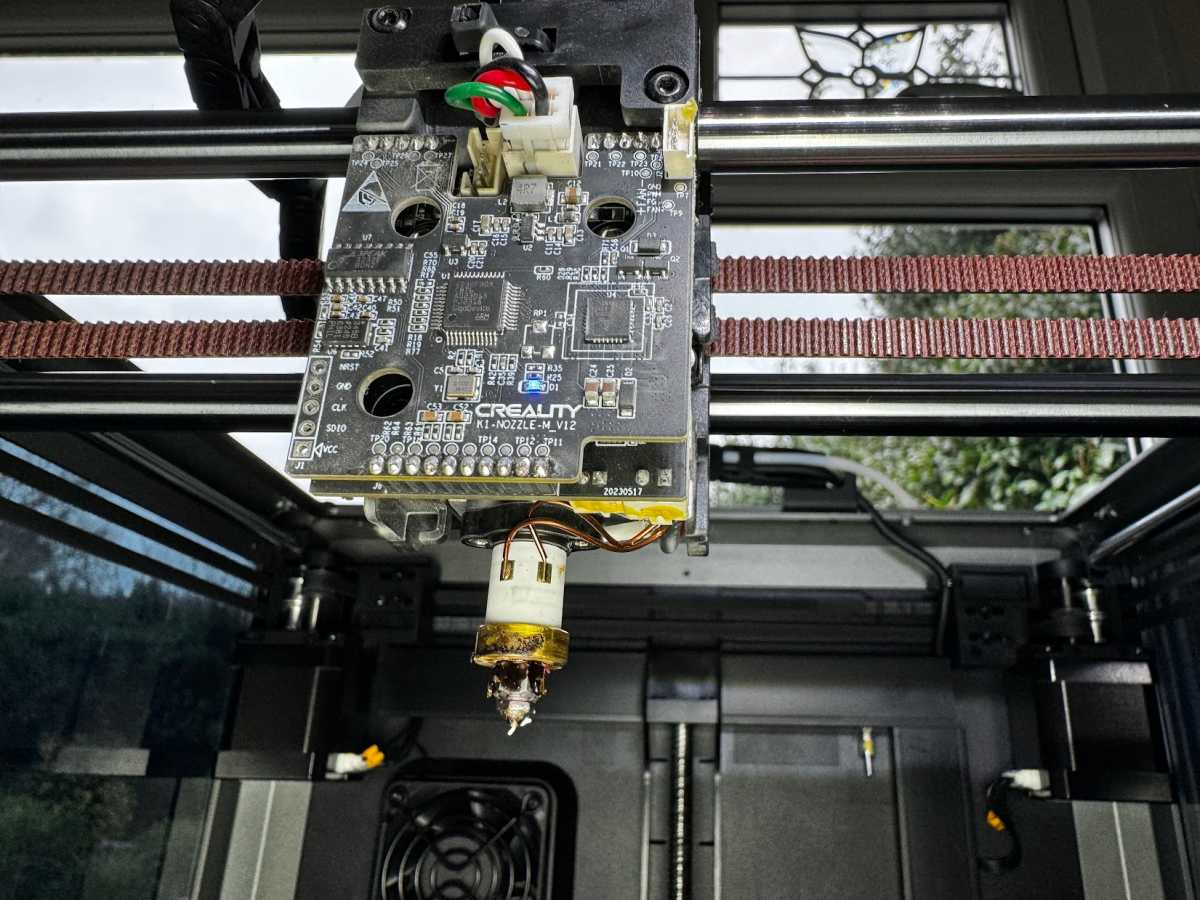

By way of meeting, there’s just about none to do: you get it out of the field, take away just a few delivery screws and foam packing, then connect the display and spool holder, plug in and away you go.

Jim Martin / Foundry

Fairly clearly, the K1C is an enclosed printer. The benefit of this design is that prime ambient temperatures will be maintained to assist preserve warping to a minimal when printing with ASA, PC and different supplies that warp all too readily.

Regardless of what Creality says about them being glass, the aspect panels are nonetheless plastic, with solely the entrance door being glass. The lid is plastic too, and must be clicked firmly into place to cease it from shifting and even falling off totally when the chain (which homes the PTFE tube for the filament and wiring for the print head) strikes to the far left aspect.

As with the K1, the PTFE tube is bent at a decent angle into the extruder which might make it troublesome or unimaginable to load filament into the new finish. Filament may catch within the run-out sensor mounted on the rear of the printer (together with the spool holder).

Jim Martin / Foundry

This implies filament adjustments will be irritating. If the filament catches on the top of the new finish, the one strategy to repair it’s to take away the lid, pull out the PTFE tube from the extruder and push the filament in manually as straight as doable till it goes in.

Examine this to Bambu’s AMS which robotically hundreds and unloads filament and it does turn out to be an enormous annoyance while you need to print in a distinct color or with a distinct sort of filament.

The 4.3in touchscreen stays the identical as on the K1 and K1 Max. Creality has made varied enhancements within the interface, with one of the crucial important being the flexibility to regulate print velocity on the fly. This was a weird absence earlier than, however it’s there now (and it really works, I’m joyful to say).

Jim Martin / Foundry

It’s nonetheless extra restricted than the controls on Creality’s Klipper-based Sonic Pad, giving choices of 125%, 75%, and 50%. There’s additionally Quiet Mode which reduces noise to “as little as” 45dB. The unhealthy information is that “as little as” is the operative phrase: it was by no means constantly quiet in my testing, with the followers and motors nonetheless being louder than you’d need.

At full chat, the K1C is exceptionally noisy – a mixture of high-flow followers and excessive print speeds. It shakes and wobbles like loopy at speeds over 300mm/sec. And whereas it might technically hit 600mm/sec (Creality even offers a check print to showcase it) it received’t obtain anyplace close to this on most prints, and might solely do it with tiny layer heights in ‘floor’ mode. The ensuing print was mighty spectacular contemplating all of the shaking about: the partitions appeared good, with no layers or imperfections seen.

Speaking of efficiency…

Efficiency

- Totally automated calibration

- 200-300mm real looking print speeds

- Dimensionally correct, clear prints

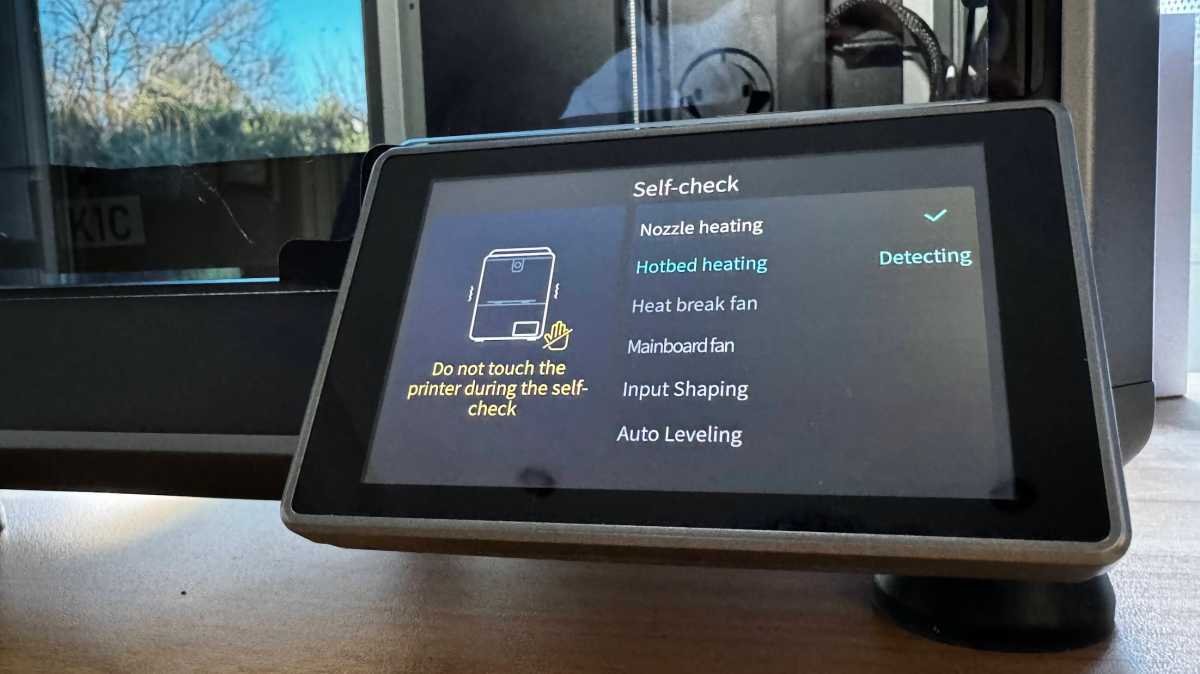

Though completely different motors are used the K1C provides the identical print speeds because the K1. A useful desk is included on a sticker contained in the printer itself, so you may make the principle settings in your slicing software program.

Jim Martin / Foundry

What’s bizarre is that Creality Print doesn’t apply these settings while you inform it what sort of filament is loaded. You possibly can choose something, however it all the time retained the identical settings for Creality’s HyperPLA, which is 200mm/sec for partitions and 300mm/sec for infill. This might have been as a result of I used to be given early entry to a construct of the software program that supported the K1C, although.

Surprisingly, even when utilizing these quicker speeds for filaments that needs to be printed slower, the K1C nonetheless delivered nice outcomes. I printed the velocity Benchy (pre-loaded as a check mannequin) in Creality’s silk PLA which was accomplished in roughly 18 minutes. I repeated the check by slicing a Benchy in Creality Print utilizing the really helpful settings, however it was troublesome to inform the distinction between the 2: each had been extremely spectacular.

There’s just about no stringing, with no wisps of filament hanging between the pillars on the boat, and no noticeable ringing on the hull.

I then printed this tiny hexagon field in PLA, which once more confirmed that retraction is great: it was very clear.

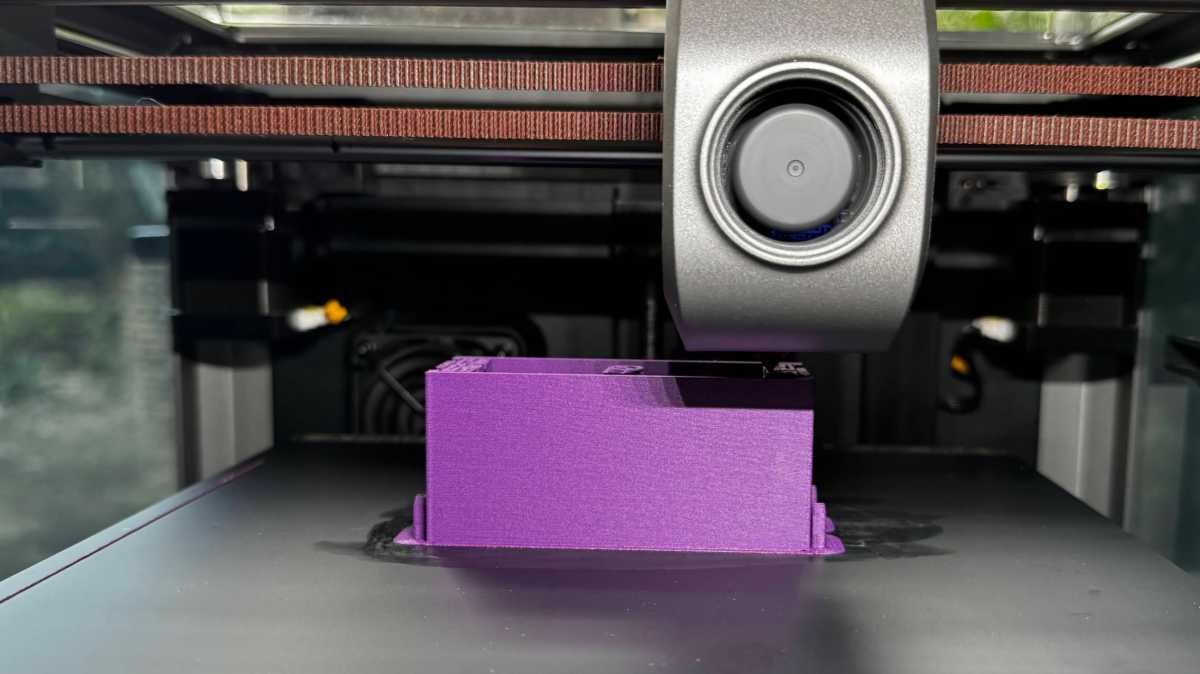

Jim Martin / Foundry

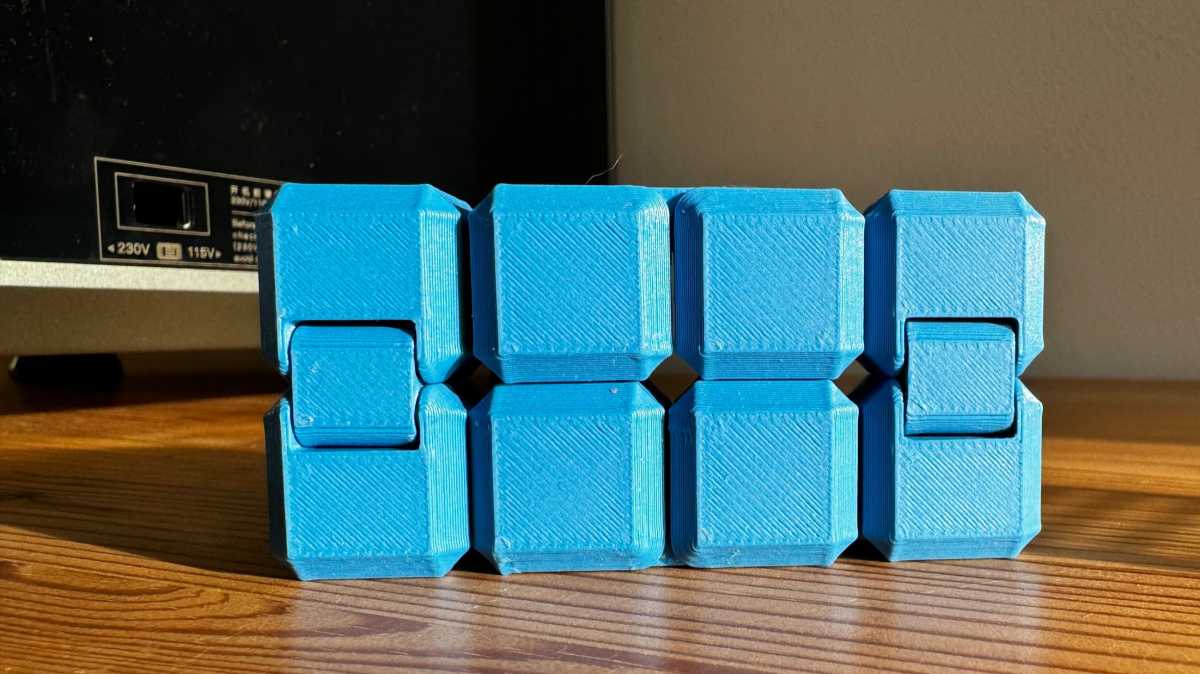

To check tolerances, I used the identical PLA to print this infinite dice fidget toy. Other than a few barely stiff hinges, which labored looser over time, it was absolutely useful proper off the construct plate.

Jim Martin / Foundry

I additionally printed a wall mounting bracket for my Ryobi space mild utilizing Creality’s wooden PLA. The half fitted completely, demonstrating that the K1C prints precisely.

I then printed quite a lot of fashions utilizing some Bambu PETG-CF and PLA-CF, all of which printed with wonderful outcomes.

Jim Martin / Foundry

Mattress adhesion was nice with all filament sorts I attempted when utilizing the really helpful glue stick. You should purchase the elective textured PEI plate, however the easy one labored completely fantastic for me and leaves the underside of prints equally easy.

Jim Martin / Foundry

The one time prints had been problematic was when utilizing PC and ASA. As you’ll be able to see from this hexagon coaster printed in ASA, the corners have warped a bit, regardless of utilizing the really helpful temperature settings.

Jim Martin / Foundry

Earlier than every print, calibration takes round 5-6 minutes. This contains heating the mattress to the specified temperature, probing the mattress (utilizing pressure gauges within the mattress) and enter shaping, which makes an attempt to counteract vibrations triggered when the print head is transferring shortly in numerous instructions.

Clearly this provides considerably to the time taken for very small fashions, however all the time price it for big prints that take hours and hours.

Print time and progress are proven on the display, however you too can see them in Creality Print and the Creality Cloud cell app. You’re free to make use of different slicing software program, however it’s best to make use of these apps to observe prints and get alerts if there’s an issue.

It’s a bit annoying that print time doesn’t change while you alter velocity on the fly. Once I tried out Quiet Mode, a print that may have taken 2h30 truly took 3h10, however it wasn’t till the print was just about completed that the time modified. Hopefully Creality can repair this in a firmware replace.

Value & availability

The Creality K1C prices $559 / £539 from Creality. That lower than the $599 / £579 that the K1 initially value.

That is good worth contemplating the upgrades, though it’s price noting that the K1 is now cheaper at $499 / £479, and that ought to embody the up to date scorching finish talked about earlier.

It actually undercuts Bambu’s P1S, which doesn’t have a touchscreen even when it does assist multi-colour printing through the corporate’s AMS.

For alternate options, see our roundup of the very best 3D printers.

Ought to I purchase the Creality K1C?

The K1C provides first rate worth for anybody in search of a flexible 3D printer that may deal with a variety of filament sorts, reliably with fast printing at top quality.

The 220x220x250 construct quantity isn’t the most important, although, and there’s no phrase but on whether or not Creality will supply an upgraded model of the K1 Max. In lots of respects, it doesn’t must because the K1 Max can – technically – already print with carbon-fibre filaments in addition to ASA, PC and nylon. You’ll simply put on out the nozzle quicker for those who do print a number of carbon fibre filament. It already has a carbon filter and a digicam.

Jim Martin / Foundry

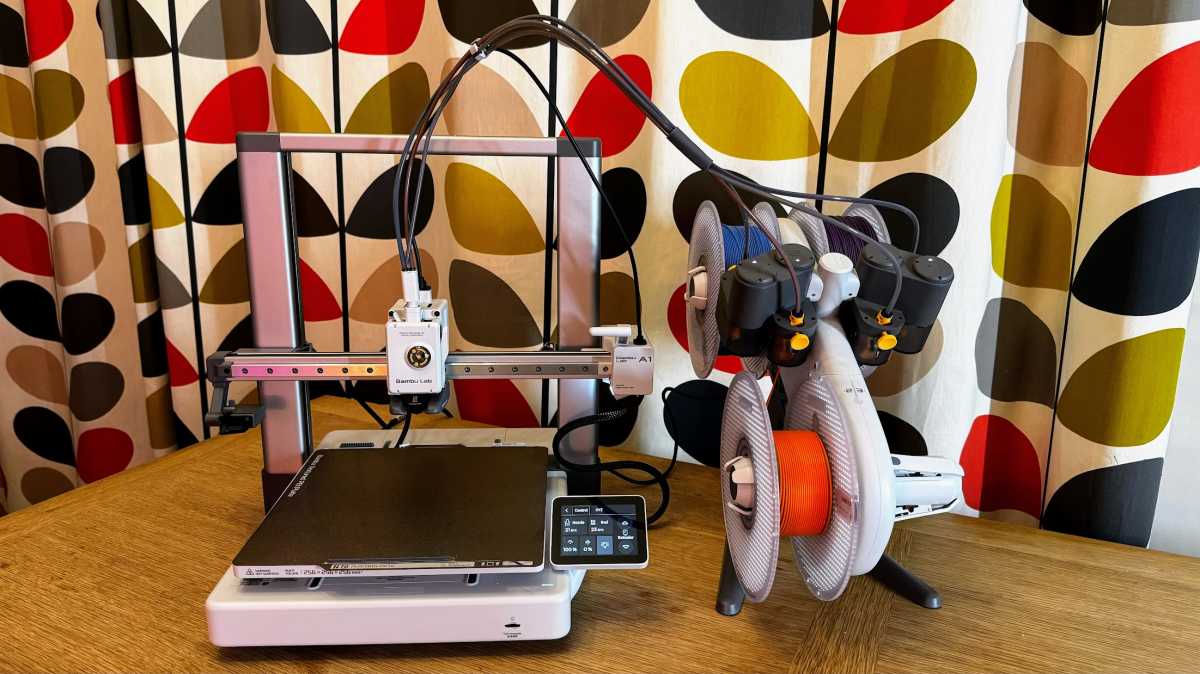

You need to take a look at the Bambu A1, although, for those who don’t must print with filaments that want an enclosure. It isn’t any noisier for it, has much more options (comparable to the flexibility to detect tangles on the filament spool) and is an efficient chunk cheaper. Oh, and it’s nonetheless cheaper than the K1C even for those who go for the A1 Combo which lets you print in as much as 4 colors thank to the AMS Mini, which can also be very handy relating to auto-changing filaments.

Admittedly, you’d want to purchase Bambu’s hardened nozzle to print with carbon fibre, however the A1 can do it simply fantastic, and provides barely extra construct quantity. It could be a mattress slinger, however it’s not a lot slower than the K1C and it produces top-notch print high quality.