The phrase “the place the rubber meets the highway” refers back to the friction level when a state of affairs will get critical. In terms of monitor racing, the rubber (the tires) are the important level of contact between the asphalt and the automobile itself. Tires make all of the distinction between a robust end on the checkered flag and a horrific slide into the wall. And in the event that they’re not working collectively, the entire system falls aside.

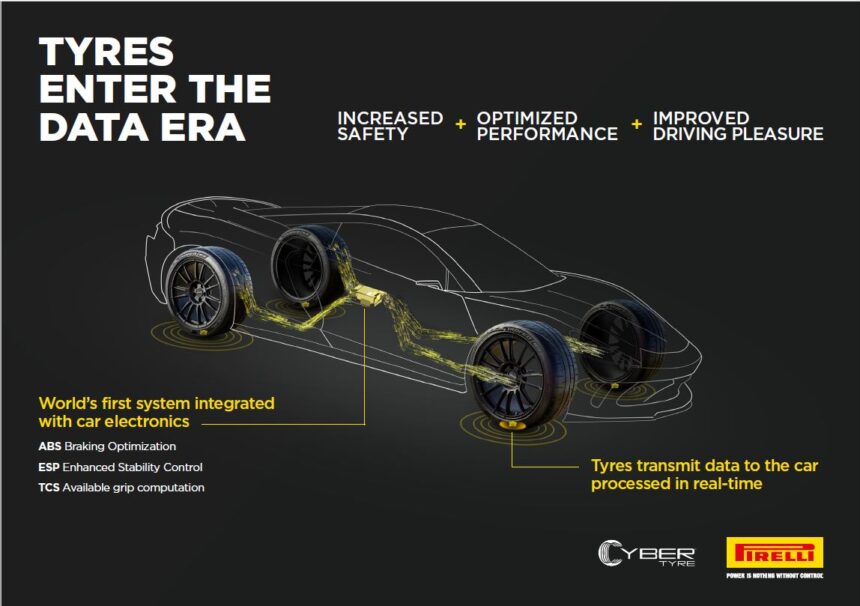

Understanding this intimately, Italian tire firm Pirelli teamed up with juggernaut know-how firm Bosch to collectively develop and create a tire communication community. As such, Pirelli “Cyber Tire” incorporates a sensor that gathers and transmits information to the automobile, making a connection that channels important info. In essence, these sensors check out the temperature of the tires, tire strain, the standing of the highway, and extra, and advise the automobile’s controllers about changes that have to be made.

It’s as if every tire is a person athlete, checking in with its sensors and chiming in with a “Put me in, coach”; or conversely, “We’d have to take the depth down a notch.”

Assume method past tire strain monitoring techniques. That is the subsequent degree of knowledge tires can gather, and the distinction is akin to evaluating a flip cellphone to a smartphone.

Tires that talk extra than simply kilos per sq. inch

Pirelli started engaged on discovering methods for its tires to “communicate” on to the automobile’s onboard pc practically 25 years in the past. Nevertheless, it’s solely within the final 12 months that the corporate developed its partnership with Bosch. Collaborating with Bosch Engineering—which is properly revered within the prestigious world of supercars like Ferrari, McLaren, and Aston Martin and in addition works carefully with typical commuter automobile producers—the tire producer harnessed the facility of the know-how large’s high-end controllers.

“The purpose was to get info from the tire, because the tire is the one level of contact between the automobile and the bottom and the place all of the forces are being transferred,” says Pierangelo Misani, Pirelli senior vice chairman and chief know-how officer. “It’s a supply of potential info that’s extraordinarily helpful for security and effectivity.”

Due to the evolution of batteries as they’ve change into smaller and extra cellular, placing a miniaturized energy supply inside a tire just isn’t the problem it as soon as was. That’s key for this utility, as a result of any added mass inside a tire can generate imbalance. Imbalance could cause vibration, which impacts consolation and security. It’s essential to have a system that’s extraordinarily mild, Misani says, and nonetheless contains elements just like the accelerometers, chip set, strain sensor, temperature sensor, and the battery. On high of that, this set of parts has to final for at the least the lifetime of the tire.

Working in a probably hostile ecosystem

There are many sensors in a automobile, some shielded from the weather and a few intentionally uncovered to water, wind, and drag drive. However inside a tire, a wholly completely different ecosystem exists. In any case, it’s inflated with air, which introduces a damp atmosphere. Second, it rolls and adjustments form, flattening with the burden of the automobile.

When the sensor rolls round to the contact patch, or the place the tire makes contact with the bottom, it has to decelerate after which re-accelerate. That’s due to the distinction within the diameter when the tire is rolling; the gap from the hub is smaller.

“We’re talking of huge acceleration, plus the sensor contained in the tire might go over bumps, a pothole, and even off-road,” Misani says. “So that you perceive the elements should be miniaturized and lightweight, however they should be additionally extraordinarily immune to the intense situations that the tire is posing to them.”

Sensors in tires aren’t new, however Pirelli’s new settlement with Bosch implies that the info of the tire is now straight transferred into the controller in actual time and used to manage the automobile. What is completely new is that the sensors are actively contributing information to the controller to manage the steadiness, braking, and traction of the automobile to create the perfect end result for that second, Misani explains. For example, if the anti-lock braking system is energetic, the automobile’s pc system doesn’t know the tire velocity or situations of the highway at that second or whether or not the tire slippage is unfavorable or constructive. With out this built-in system, the ABS has to guess on the situations and won’t maximize the capabilities of the tires.

Pirelli goals to handle hydroplaning, a dreaded highway situation that occurs when your tires can’t channel sufficient water away from the tread and automobile management turns into a serious problem.

“Hydroplaning implies that the contact patch turns into shorter and shorter till it’s lifted,” Misani describes. “It’s like a ship that’s lifting from the water, inflicting you to lose contact with the bottom. The much less contact with the bottom, the much less functionality it’s a must to speed up, brake, or steer. With the sensor, we’re capable of detect if there may be hydroplaning.”

Pirelli’s CTO additionally says one other characteristic the corporate is engaged on is algorithms that may predict or to detect the efficient put on fee of the tire and at which stage of its life the tire is.

Sharing the know-how

Whereas hypercar builder Pagani is the primary to make use of the built-in sensors in its 850-horsepower Utopia Roadster, Pirelli has set its sights on a much wider utility.

“Within the Pagani Utopia Roadster, we’re capable of actively ship the info from the sensor to the receiver that interacts with the controller system of the automobile and actively tells the ABS, stability management, and the traction management the right way to get the perfect response for that situation,” Misani says. “It was the primary proof of idea that we will present to different OEMs to indicate that it really works.”

In the end, Misani says Pirelli desires to share this know-how with different producers.

“That is the long run. We’re the primary one to have it, however we don’t need to maintain it just for ourselves,” he emphasizes. “It’s a method to enhance security and must be out there additionally to others.”